Amorphous alloy oil transformer

- Low loss: the core of transformer is coiled by amorphous alloy, and the no-load loss ratio is about 75% lower than that of S9 transformer

- Resistant to short-circuit: the transformer low voltage is made of copper foil coil to increase the capacity for undertaking short-circuit.

- Optimize the power quality: the connection group of transformer is Dynll to reduce the influence of harmonic on grid and improve the power quality.

- Maintenance-free: the tank and cover are an integrated fully-enclosed structure, long in service life and free in maintenance.

- Good insulating property: the transformer is filled with oil in a vacuum mode to completely eliminate the bubbles in coil and ensure the stable insulating property

- Installed in high-rise buildings, business centers, metros, airports, stations, industrial and mining enterprises and power plants, especially applicable to the places with high fire protection requirements such as inflammables and explosives.

Product Details

DOWNLOAD

DOWNLOAD

-

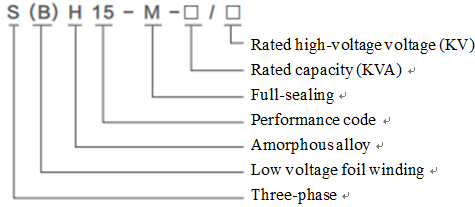

Model Description

-

Features

- Low loss: the core of transformer is coiled by amorphous alloy, and the no-load loss ratio is about 75% lower than that of S9 transformer

- Resistant to short-circuit: the transformer low voltage is made of copper foil coil to increase the capacity for undertaking short-circuit.

- Optimize the power quality: the connection group of transformer is Dynll to reduce the influence of harmonic on grid and improve the power quality.

- Maintenance-free: the tank and cover are an integrated fully-enclosed structure, long in service life and free in maintenance.

- Good insulating property: the transformer is filled with oil in a vacuum mode to completely eliminate the bubbles in coil and ensure the stable insulating property

-

Conditions of Use

- Indoors or outdoors with the elevation of less than 1,000m

- Maximum ambient temperature: +40℃, maximum daily mean temperature: +30℃

- Maximum annual average temperature: +20℃, minimum temperature: -25℃

- Transformer for special conditions can be provided according to the user's requirements

-

Technical ParametersRated capacity KVA

Voltage combinations and tapping ranges

Grade mark of connection group

Voltage combinations and tapping ranges

Short-circuit impedance (%)

No-load current (%)

Sound level LpA (dB)

High voltage (KV)

Tapping (%)

Low voltage (KV)

No-load (P0)

Load (Pk) (75℃)

30

6 6.3 10 10.5 11

±5 ±2×2.5

0.4

Dyn11

Yzn11

Yyn033

630/600

4

1.5

52

50

43

910/870

1.2

53

63

50

1090/1040

1.1

53

80

60

1310/1250

1

55

100

75

1580/1500

0.9

55

125

85

1890/1800

0.8

59

160

100

2310/2200

0.6

59

200

120

2730/2600

0.6

61

250

140

3200/3050

0.6

61

315

170

3830/3650

0.5

64

400

200

4520/4300

0.5

64

500

240

5410/5150

0.5

66

630

320

6200

4.5

0.3

66

800

Dyn11

Yyn0380

7500

0.3

68

1000

450

10300

0.3

68

1250

530

12000

0.2

72

1600

630

14500

0.2

72

2000

750

18300

5

0.2

73

2500

900

21220

0.2

73

Note: 1: When the iron core is three-phase and three-column, Yyn0 connection group can be used according to the need.

2: For the transformer with the rated capacity of 500KVA and below, the load loss above the inclined line of table is applicable to Dyn11 connection group, and the load loss below the inclined line is applicable to Yyn0 connection group.

3: Other loss values can be used if the user needs.

4: Other high voltage tapping three-phase transformers can be provided according to the user's need

-

-

-

-